PE PP Sheet Extruder Machine,PA POM Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

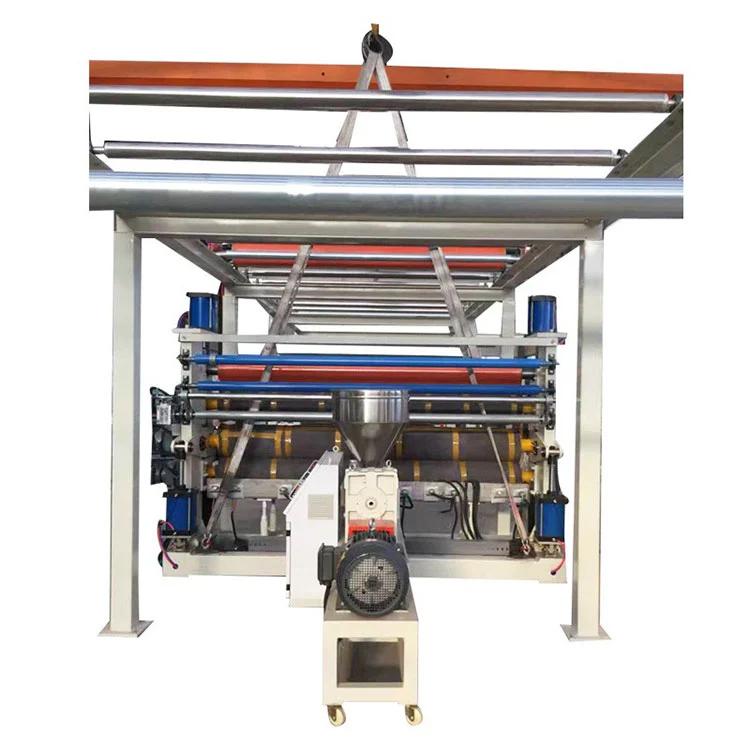

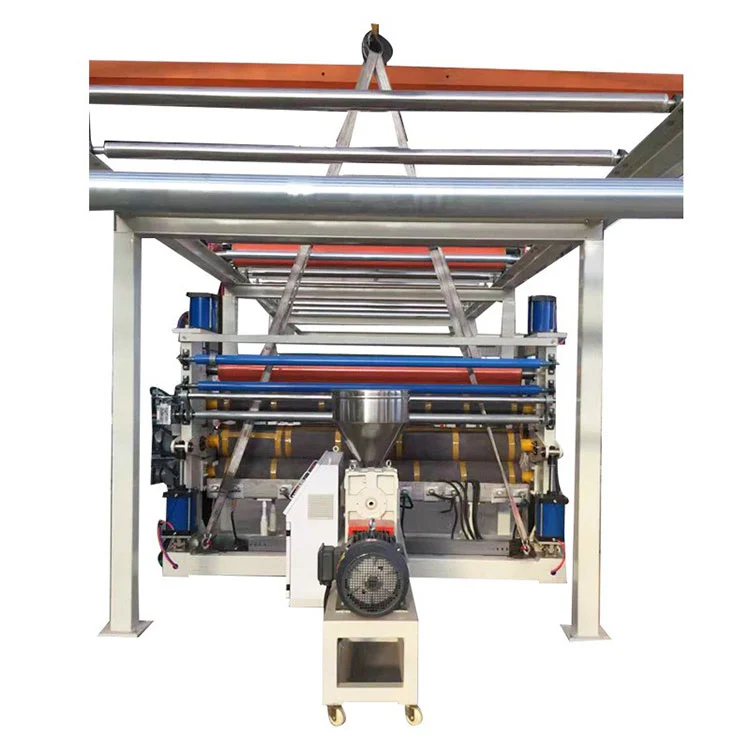

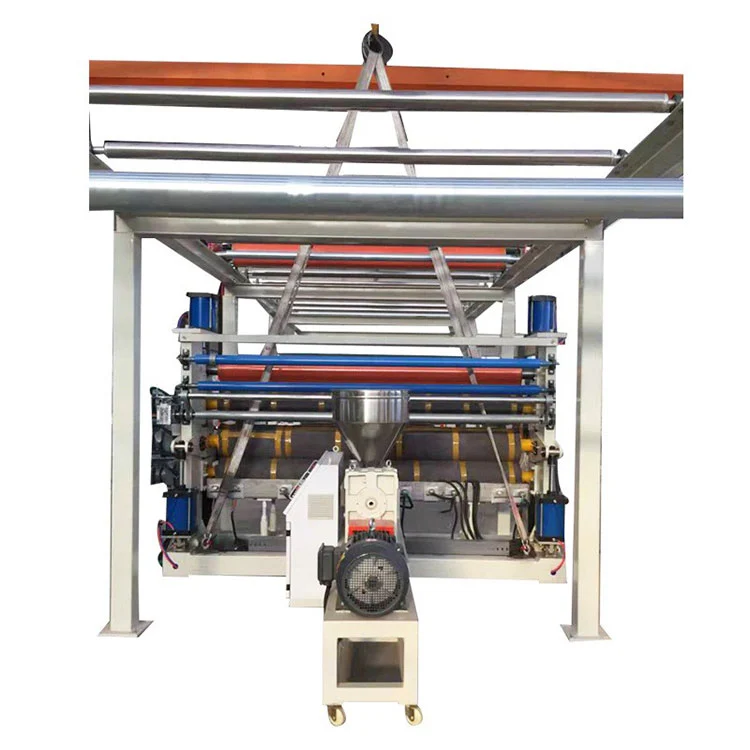

In a world where automotive accessories demand precision, durability, and eco-friendliness, the TPE Car Mat Sheet Extruder Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a beacon of innovation. Designed specifically for producing high-quality thermoplastic elastomer (TPE) car mat sheets, this machine transforms raw materials into resilient, non-slip, and easy-to-clean automotive floor coverings. Its advanced extrusion technology ensures seamless production of mats that protect vehicle interiors from dirt, moisture, and wear, enhancing both aesthetics and functionality. Whether for OEM suppliers or aftermarket manufacturers, this machine streamlines the creation of car mats that meet rigorous industry standards while offering customization in colors, textures, and thicknesses.

This extruder machine boasts a range of core benefits that set it apart. Crafted with precision engineering, it utilizes high-grade components for long-lasting performance, reducing downtime and maintenance costs. The intelligent control system allows for real-time monitoring and adjustments, ensuring consistent output with minimal waste. Unlike traditional methods, it supports eco-friendly TPE materials, which are recyclable and free from harmful chemicals, aligning with global sustainability trends. Additionally, the machine's modular design enables quick customization for different production scales, from small batches to high-volume runs. With a focus on energy efficiency, it lowers operational costs while delivering mats that offer superior grip, weather resistance, and comfort—key factors that delight end-users.

Many manufacturers face issues like inconsistent mat thickness, high material waste, and slow production speeds. The TPE Car Mat Sheet Extruder Machine tackles these head-on with its innovative features. For instance, the integrated cooling system ensures uniform sheet formation, preventing warping or defects. Below is a table summarizing key parameters that highlight its efficiency:

| Parameter | Specification |

|---|---|

| Extrusion Output | Up to 500 kg/h |

| Sheet Width Range | 1000-2000 mm |

| Thickness Tolerance | ±0.1 mm |

| Power Consumption | Optimized for 20% savings vs. standard models |

| Noise Level | < 75 dB |

This data reflects how the machine solves common pain points, such as reducing energy use by 20% compared to competitors, thereby cutting costs and environmental impact.

This machine is tailored for automotive parts manufacturers, car mat producers, and recycling facilities seeking to upgrade their production lines. It excels in scenarios like mass-producing custom-fit mats for various vehicle models, from sedans to SUVs, or creating anti-fatigue mats for commercial fleets. In workshops, it enables rapid prototyping for new designs, while large factories benefit from its scalability. By integrating this extruder, businesses can cater to markets demanding premium, eco-conscious products, such as electric vehicle manufacturers or luxury car brands.

Using this machine evokes a sense of pride and reliability. For manufacturers, it means fewer rejects and higher profitability, as the consistent quality reduces returns and boosts customer satisfaction. End-users enjoy car mats that stay in place, resist stains, and last for years, eliminating the frustration of frequent replacements. Emotionally, it fosters trust—knowing that each mat is crafted with precision technology from Qingdao Eaststar Plastic Machinery Co., Ltd., users feel assured of safety and comfort during daily drives. This solution not only solves practical issues like mud accumulation or odor but also enhances the overall driving experience, making interiors feel premium and well-maintained.

What makes this extruder unique is its blend of versatility and sustainability. Unlike PVC-based alternatives, it specializes in TPE, which is softer, more flexible, and environmentally friendly. The machine's dual-stage extrusion process ensures better material dispersion, resulting in mats with enhanced tensile strength and UV resistance. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. incorporates user-friendly interfaces and remote diagnostics, allowing operators to troubleshoot issues quickly—a rarity in conventional machines. This focus on innovation means customers gain a competitive edge, producing mats that not only meet but exceed regulatory standards like REACH and RoHS.

What is the typical lifespan of the TPE Car Mat Sheet Extruder Machine?

With proper maintenance, this machine can operate efficiently for over 10 years. Regular cleaning and part checks, as outlined in the manual, help maximize durability. Qingdao Eaststar Plastic Machinery Co., Ltd. provides comprehensive support, including spare parts and technical services, to ensure long-term performance.

Can it handle recycled TPE materials?

Yes, the extruder is designed to process both virgin and recycled TPE, supporting circular economy initiatives. It includes filters and mixers that ensure consistent quality even with reclaimed materials, reducing waste and costs.

How does the machine ensure consistent sheet thickness?

It features an automatic thickness control system with sensors that monitor the extrusion process in real-time. Any deviations trigger immediate adjustments, maintaining precision within ±0.1 mm across the entire sheet.

Is training provided for operators?

Absolutely. Qingdao Eaststar Plastic Machinery Co., Ltd. offers onsite or online training sessions covering operation, safety, and basic troubleshooting. This ensures your team can use the machine effectively from day one.

What safety features are included?

The machine comes with emergency stop buttons, overload protection, and insulated components to prevent accidents. It complies with international safety standards, ensuring a secure working environment.

Can it be customized for specific production needs?

Yes, modular components allow for adaptations in output speed, sheet dimensions, and color mixing. Discuss your requirements with the Qingdao Eaststar team to tailor the machine to your unique setup.

How energy-efficient is this extruder compared to others?

It uses advanced servo motors and heat recovery systems, cutting energy consumption by up to 20% versus standard models. This not only lowers electricity bills but also reduces your carbon footprint.

What kind of after-sales support is available?

Qingdao Eaststar Plastic Machinery Co., Ltd. provides a 1-year warranty, 24/7 customer service, and access to a global network of technicians. Spare parts are readily available to minimize downtime.

Does it support automation for high-volume production?

Yes, the machine can integrate with conveyor systems and robotic arms for fully automated lines. This boosts productivity, making it ideal for large-scale manufacturing.

Are the produced mats suitable for all weather conditions?

Definitely. TPE mats from this extruder offer excellent resistance to temperature extremes, water, and UV rays, ensuring they perform well in diverse climates without cracking or fading.