PE PP Sheet Extruder Machine,PA POM Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

Welcome to a world where innovation meets industrial excellence. The PVDF Sheet Extruder Machine, proudly crafted by Qingdao Eaststar Plastic Machinery Co., Ltd., is engineered to redefine the standards of polymer processing. Designed for precision, durability, and efficiency, this machine empowers industries to produce high-quality PVDF sheets that meet rigorous demands across various sectors. Whether you're in chemical processing, construction, or electronics, our extruder ensures superior performance, making it an indispensable asset for modern manufacturing.

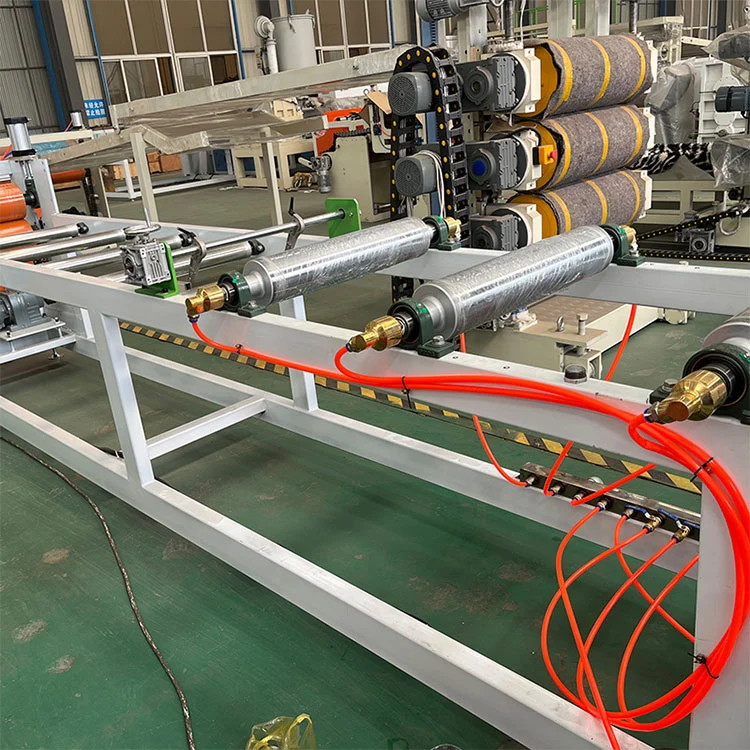

PVDF Sheet Extruder Machine in operation" />

PVDF Sheet Extruder Machine in operation" />

At the heart of Qingdao Eaststar Plastic Machinery Co., Ltd.'s PVDF Sheet Extruder Machine lies a fusion of cutting-edge technology and robust design. This equipment excels in transforming raw PVDF (Polyvinylidene Fluoride) materials into uniform, high-strength sheets with exceptional chemical resistance, thermal stability, and mechanical properties. The extruder operates seamlessly to deliver consistent output, minimizing waste and maximizing productivity. By incorporating intelligent control systems, it allows operators to fine-tune parameters for customized sheet thickness, width, and surface finish, ensuring every batch meets exact specifications.

Many manufacturers face issues like inconsistent sheet quality, high energy consumption, and frequent downtime. Our PVDF Sheet Extruder Machine addresses these pain points head-on. With its optimized screw design and efficient heating zones, it ensures uniform melting and extrusion, reducing material defects. For instance, in scenarios where corrosion resistance is critical, such as chemical tank linings, this machine produces sheets that withstand harsh environments without degradation. The table below highlights key parameters that demonstrate its capability:

| Parameter | Specification |

|---|---|

| Output Capacity | Up to 500 kg/h |

| Sheet Thickness Range | 0.5 mm to 10 mm |

| Power Consumption | Optimized for energy savings, typically 15-20% lower than competitors |

| Temperature Control Accuracy | ±1°C |

| Machine Dimensions | Customizable to fit various production spaces |

This machine is ideal for a wide range of professionals, including industrial manufacturers, chemical plant operators, construction material suppliers, and R&D laboratories. In chemical processing, it creates corrosion-resistant sheets for piping and containers. In architecture, it produces durable panels for cladding and roofing. Electronics manufacturers use PVDF sheets for insulation, benefiting from the material's dielectric properties. No matter the application, users experience a seamless integration into their workflows, boosting overall efficiency and product reliability.

Imagine the confidence of delivering flawless products every time. Users of Qingdao Eaststar's PVDF Sheet Extruder Machine report significant improvements in production consistency and cost savings. By eliminating common issues like warping or uneven surfaces, it reduces rework and enhances customer satisfaction. Operators feel empowered by the user-friendly interface, which simplifies monitoring and adjustments. This not only solves operational headaches but also fosters a sense of pride in producing top-tier materials that stand the test of time.

Compared to standard extruders, Qingdao Eaststar Plastic Machinery Co., Ltd.'s PVDF Sheet Extruder Machine offers distinct advantages. Its dual-stage cooling system ensures rapid and uniform sheet solidification, preventing internal stresses. The machine incorporates anti-clogging technology, which reduces maintenance intervals and extends service life. Additionally, compatibility with various PVDF grades allows for versatility in production. These innovations, backed by rigorous testing, set it apart as a leader in the market, providing unmatched value for investment.

What is the typical lead time for delivery and installation?

Delivery usually takes 4-6 weeks after order confirmation, with installation support available globally to ensure smooth setup and operation.

Can the machine handle recycled PVDF materials?

Yes, it is designed to process both virgin and recycled PVDF, with adjustable settings to maintain quality and consistency in output.

How does the energy efficiency compare to older models?

This extruder incorporates advanced insulation and variable frequency drives, reducing energy consumption by up to 20% compared to conventional machines.

Is training provided for operators?

Comprehensive training sessions are offered, covering operation, maintenance, and troubleshooting, to maximize uptime and productivity.

What warranty and support options are available?

Qingdao Eaststar provides a standard 2-year warranty on core components, along with 24/7 technical support for any inquiries or issues.

The versatility of the PVDF Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. makes it suitable for multiple industries. In the medical field, it produces sterile, non-reactive sheets for equipment housings. For renewable energy sectors, it manufactures components for solar panels due to PVDF's UV resistance. Each application benefits from the machine's precision, ensuring that sheets meet specific regulatory and performance standards. By adapting to various production scales—from small batches to high-volume runs—it supports business growth without compromising on quality.

Beyond performance, this extruder promotes environmental responsibility. Its energy-efficient design lowers carbon footprints, while the ability to use recycled materials supports circular economy initiatives. Users appreciate the long-term savings from reduced waste and lower maintenance costs, making it a smart investment for forward-thinking companies. The machine's durability, with components crafted from high-grade materials, ensures years of reliable service, minimizing the need for replacements and contributing to sustainable operations.

For those seeking deeper understanding, the PVDF Sheet Extruder Machine integrates features like PLC-based automation for precise control over extrusion parameters. The table below expands on additional specifications:

| Feature | Details |

|---|---|

| Screw Diameter Options | Available in 60mm, 80mm, and 100mm for different throughput needs |

| Heating Zones | Up to 8 zones with individual PID control for uniform temperature distribution |

| Cooling Method | Combined air and water cooling for optimal efficiency |

| Noise Level | Below 75 dB, ensuring a comfortable working environment |

Businesses worldwide have shared positive feedback on the PVDF Sheet Extruder Machine. A chemical manufacturer in Europe noted a 30% increase in production efficiency after switching to Qingdao Eaststar's equipment. Similarly, a construction firm in Asia reported fewer defects and faster project completion times. These real-world successes highlight the machine's reliability and the trust placed in Qingdao Eaststar Plastic Machinery Co., Ltd. as a partner in innovation.

Understanding that every production line is unique, Qingdao Eaststar offers customization options for the PVDF Sheet Extruder Machine. From tailored control interfaces to specific output sizes, the machine can be adapted to meet individual requirements. Post-sale support includes regular maintenance checks and software updates, ensuring continuous improvement and adaptation to evolving industry standards. This commitment to customer care reinforces the machine's value as a long-term solution for demanding applications.

In an era of rapid technological advancement, investing in the PVDF Sheet Extruder Machine means staying ahead of the curve. Its modular design allows for easy upgrades, such as integrating IoT sensors for real-time monitoring and predictive maintenance. This forward-thinking approach not only enhances operational efficiency but also prepares businesses for Industry 4.0 challenges. By choosing Qingdao Eaststar Plastic Machinery Co., Ltd., you are not just purchasing a machine; you are embracing a partnership dedicated to innovation and success.