PE PP Sheet Extruder Machine,PA POM Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

Welcome to a world where innovation meets practicality in industrial and commercial settings. The PVC Soft Door Curtain Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. redefines how businesses manage spaces with flexible, durable door solutions. This advanced machinery is engineered to produce high-quality PVC soft door curtains that serve as effective barriers against dust, insects, noise, and temperature fluctuations. Whether it's for warehouses, food processing plants, or retail stores, this machine empowers you to create custom curtains that enhance energy efficiency, safety, and workflow. By integrating cutting-edge extrusion technology, it ensures consistent output, making it an indispensable tool for modern facilities seeking reliable, cost-effective partitioning solutions.

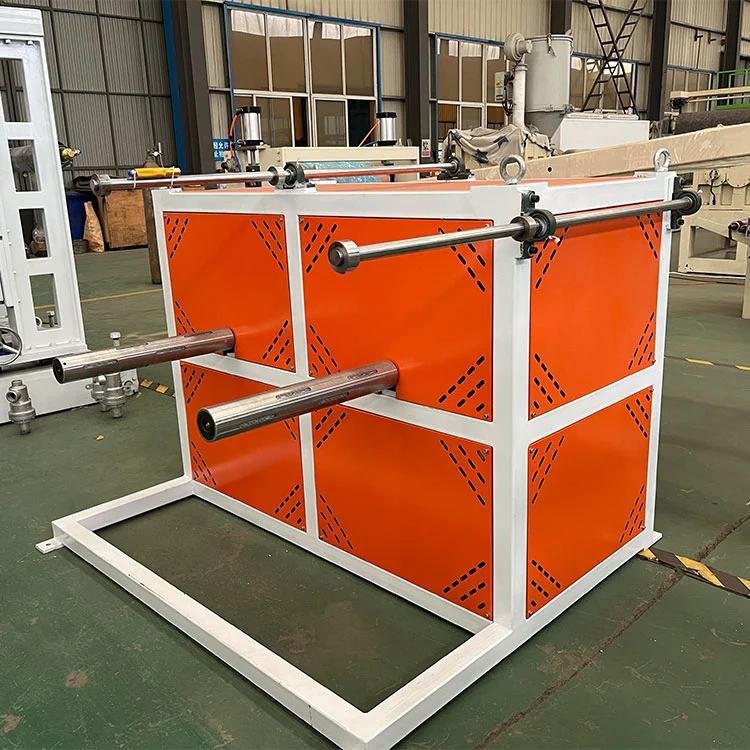

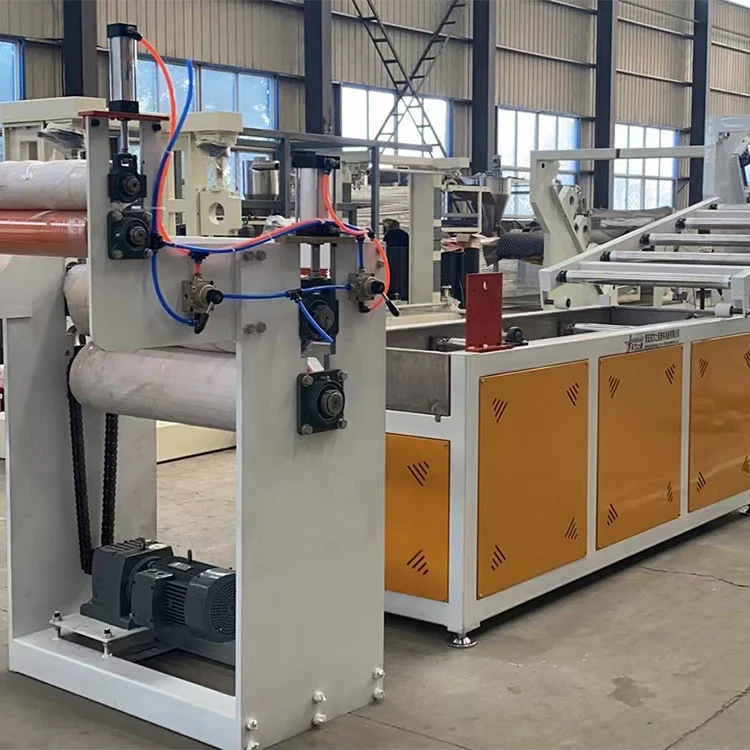

What sets the PVC Soft Door Curtain Machine apart is its blend of precision engineering and user-centric design. Crafted with high-grade materials, it boasts exceptional durability and resistance to wear, ensuring long-term operation without frequent maintenance. The machine incorporates state-of-the-art control systems that allow for easy adjustments, enabling seamless production of curtains in various thicknesses and sizes. Its energy-efficient motors reduce operational costs, while the automated features minimize manual intervention, boosting productivity. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs each unit with rigorous quality checks and comprehensive warranties, giving you peace of mind and confidence in your investment. From enhanced safety with smooth operation to eco-friendly production processes, this machine delivers tangible benefits that translate into higher ROI for your business.

In many industrial environments, common issues like energy loss, contamination, and inefficient space management can hinder growth. The PVC Soft Door Curtain Machine addresses these by offering tailored solutions. For instance, in cold storage facilities, heat escape through doors can spike energy bills. Our machine produces insulating curtains that maintain temperature integrity. Similarly, in manufacturing plants, dust and debris infiltration can compromise product quality—our curtains act as effective shields. Below is a table outlining key parameters to help you match the machine to your specific needs:

| Parameter | Specification | Benefit |

|---|---|---|

| Production Speed | Up to 10 meters per minute | Fast output for high-demand settings |

| Material Compatibility | PVC, with options for reinforced layers | Versatility for various applications |

| Power Consumption | Low energy, approx. 5-7 kW | Cost savings and environmental friendliness |

| Customization Range | Width: 0.5-2 meters, Thickness: 1-3 mm | Fits diverse door sizes and requirements |

This machine is perfect for a wide array of industries and professionals. Warehouse managers can use it to create curtains that facilitate smooth traffic flow while keeping out pests and contaminants. Food processing plants benefit from hygiene-compliant barriers that prevent cross-contamination. Retail outlets and supermarkets find it useful for maintaining climate control in entryways. Even agricultural sectors employ these curtains in greenhouses or livestock areas to regulate environments. Essentially, anyone involved in logistics, manufacturing, or commercial operations where space division and protection are crucial will find the PVC Soft Door Curtain Machine an invaluable asset. Its adaptability makes it suitable for both small businesses and large corporations looking to optimize their infrastructure.

Imagine walking into your facility and feeling a immediate sense of order and cleanliness. With curtains produced by this machine, users experience reduced stress from fewer maintenance issues and lower utility costs. The quiet, reliable operation means no disruptive noises, fostering a more pleasant work environment. For business owners, it translates into pride in a well-organized space that boosts employee morale and customer impressions. By solving problems like energy waste and contamination, it brings a feeling of control and progress, turning daily challenges into opportunities for growth and innovation.

Unlike standard machines, the PVC Soft Door Curtain Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. incorporates proprietary extrusion technology that ensures uniform material distribution, resulting in curtains with superior tear resistance and longevity. Its user-friendly interface includes touch-screen controls and remote monitoring capabilities, setting it apart in terms of ease of use. Additionally, the machine supports quick mold changes, allowing for rapid adaptation to different production runs without downtime. Comparative tests show it outperforms others in energy efficiency by up to 20%, thanks to optimized motor designs. These unique aspects, combined with responsive customer support, make it a leader in the market.

What types of materials can the PVC Soft Door Curtain Machine process?

The machine is primarily designed for PVC materials, but it can handle variations including reinforced PVC with additives for extra strength or transparency. This flexibility allows for production of curtains suited to specific environmental conditions, such as high-moisture areas or places requiring UV resistance.

How easy is it to operate the machine for someone with limited technical experience?

It features an intuitive control panel with pre-set programs and step-by-step guides, making it accessible for operators of all skill levels. Training sessions and manuals provided by Qingdao Eaststar Plastic Machinery Co., Ltd. ensure quick mastery, typically within a few days of use.

What maintenance routines are recommended to ensure long-term performance?

Regular cleaning of extrusion heads and lubrication of moving parts are advised, along with periodic checks on electrical components. The machine is built for low maintenance, with most tasks requiring simple tools and minimal time, helping to avoid costly downtimes.

Can the machine produce custom sizes and designs for unique applications?

Yes, it offers extensive customization options through adjustable settings and interchangeable molds. Whether you need curtains with specific widths, colors, or patterns, the machine can be tailored to meet exact specifications, supported by technical assistance from our team.

What is the typical lifespan of curtains produced by this machine?

Curtains manufactured using this equipment typically last 3-5 years under normal conditions, depending on usage intensity and environmental factors. The high-quality output ensures durability, reducing the need for frequent replacements and providing consistent performance.