PE PP Sheet Extruder Machine,PA POM Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

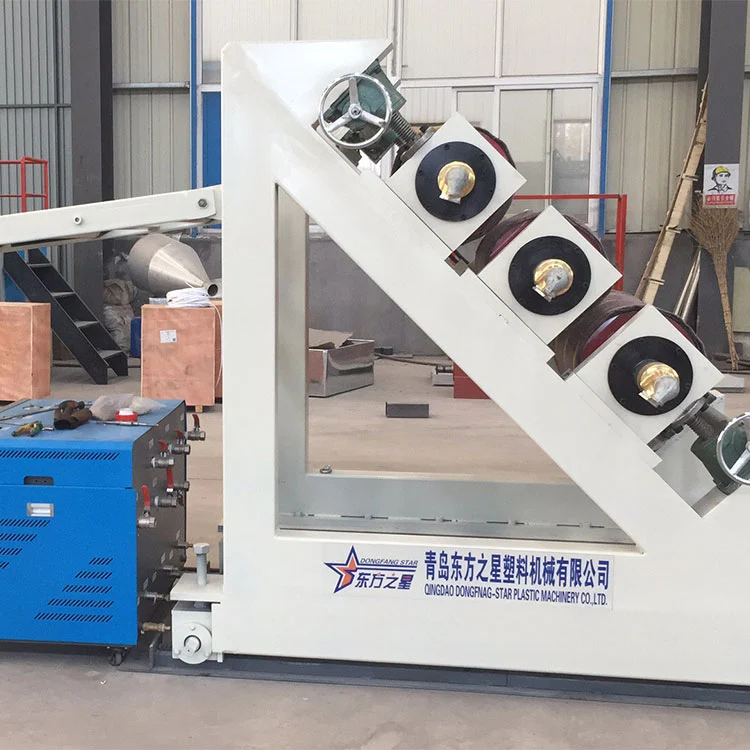

At Qingdao Eaststar Plastic Machinery Co., Ltd., we take pride in engineering cutting-edge solutions that redefine industrial efficiency. Our POM Sheet Extruder Machine is a testament to innovation, designed specifically for producing high-quality polyoxymethylene (POM) sheets with unparalleled precision. This advanced machine transforms raw POM materials into durable, dimensionally stable sheets ideal for various demanding applications. Whether you're in automotive manufacturing, consumer electronics, or precision engineering, this extruder ensures consistent output that meets rigorous industry standards. By integrating state-of-the-art technology, we've created a system that not only boosts productivity but also minimizes waste, making it a smart investment for forward-thinking businesses.

The core of this machine lies in its ability to handle POM's unique properties, such as low friction, high stiffness, and excellent chemical resistance. With a focus on user-friendly operation, it streamlines the entire extrusion process from material feeding to sheet formation. Imagine achieving flawless sheets with smooth surfaces and tight tolerances, every single time. That’s the reliability Qingdao Eaststar Plastic Machinery Co., Ltd. delivers. Our machine is built to withstand continuous operation, reducing downtime and maximizing your return on investment. It’s more than just equipment; it’s a partner in your production journey, empowering you to create superior products that stand out in competitive markets.

What sets our POM Sheet Extruder Machine apart is its blend of robust construction and intelligent design. Crafted from premium materials, it ensures longevity and resistance to wear, even in high-stress environments. The extrusion screw and barrel are precision-engineered to handle POM's specific melt characteristics, preventing issues like degradation or uneven flow. This results in sheets with excellent mechanical properties, such as high tensile strength and impact resistance, which are crucial for applications like gears, bearings, and electrical components. Additionally, the machine features advanced temperature control systems that maintain optimal processing conditions, guaranteeing consistent quality batch after batch.

We understand that efficiency is key in today's fast-paced industries. That's why our extruder incorporates energy-saving mechanisms that reduce power consumption without compromising output. The automated controls allow for easy adjustments, making it accessible for both seasoned operators and newcomers. With a commitment to sustainability, Qingdao Eaststar Plastic Machinery Co., Ltd. ensures that our machines adhere to environmental standards, helping you contribute to a greener planet. From reduced material waste to lower energy bills, the benefits extend beyond the production line, fostering a sense of pride in using technology that cares.

Many manufacturers face hurdles like inconsistent sheet thickness, high scrap rates, or frequent machine breakdowns when working with POM. Our POM Sheet Extruder Machine addresses these pain points head-on. For instance, if you've struggled with warping or dimensional inaccuracies, our solution includes a precision calibration system that ensures uniform thickness across the entire sheet. This eliminates rework and enhances product reliability. Below, we outline some common scenarios and how our machine provides effective solutions, backed by technical specifications:

Scenario: Inconsistent melting leading to weak spots in sheets.

Solution: Multi-zone temperature control with real-time monitoring for stable melt flow.

| Parameter | Specification |

|---|---|

| Extrusion Capacity | Up to 500 kg/h |

| Sheet Width Range | 500-2000 mm |

| Thickness Tolerance | ±0.1 mm |

| Power Consumption | Optimized to reduce by 15% compared to standard models |

| Operating Temperature | 180-220°C (adjustable in 5 zones) |

Another common issue is the difficulty in handling POM's sensitivity to moisture, which can cause bubbles or defects. Our machine comes equipped with a integrated drying hopper that pre-treats the material, ensuring optimal moisture content before extrusion. This proactive approach saves time and resources, allowing you to focus on innovation rather than troubleshooting. By leveraging these features, users report a significant reduction in production errors and an increase in overall efficiency. It’s not just about fixing problems; it’s about elevating your capabilities to new heights.

This POM Sheet Extruder Machine is ideal for a diverse range of professionals and industries. Automotive parts manufacturers rely on it for producing durable components like fuel system parts and interior trim, where precision and reliability are non-negotiable. In the electronics sector, it’s used to create insulating sheets and connectors that demand high dielectric strength. Even in medical device manufacturing, the machine’s ability to produce clean, biocompatible sheets makes it invaluable. Small to large-scale factories, research institutions, and custom fabricators will find it adaptable to their needs, whether for mass production or specialized projects.

Consider a scenario in a busy industrial plant where downtime can cost thousands per hour. With this extruder, operators experience smoother workflows and fewer interruptions. The intuitive interface reduces the learning curve, enabling teams to achieve peak performance quickly. For business owners, it translates to higher output rates and better profit margins. By choosing Qingdao Eaststar Plastic Machinery Co., Ltd., you’re not just buying a machine; you’re investing in a tool that grows with your business, adapting to evolving demands while maintaining top-tier quality.

Using our POM Sheet Extruder Machine often leads to a profound sense of accomplishment. Imagine the relief of no longer dealing with erratic production runs or customer complaints about subpar products. Instead, you’ll feel a surge of pride as each sheet rolls out perfectly, knowing that your offerings meet the highest standards. This machine solves the underlying anxiety of unmet deadlines and quality issues, replacing it with confidence and control. Users frequently share stories of how it has revitalized their operations, allowing them to take on more ambitious projects and build stronger client relationships. It’s about transforming daily struggles into seamless, rewarding experiences.

Beyond practical benefits, there’s an emotional ripple effect. Teams feel more motivated when equipped with reliable technology, fostering a culture of excellence. Business leaders enjoy peace of mind, knowing their investment is backed by Qingdao Eaststar Plastic Machinery Co., Ltd.’s reputation for durability and support. This machine doesn’t just produce sheets; it builds trust and drives growth, making every user feel like they’re at the forefront of their industry.

In a market flooded with alternatives, our POM Sheet Extruder Machine shines through its unique combination of innovation and practicality. Unlike many competitors, we incorporate a proprietary screw design that enhances mixing and reduces shear heat, which is critical for POM’s processing. This minimizes the risk of material degradation, ensuring longer machine life and superior sheet quality. Additionally, our aftersales service includes comprehensive training and timely maintenance support, a rarity in the industry. While others may offer similar specs, Qingdao Eaststar Plastic Machinery Co., Ltd. focuses on holistic value—from initial setup to long-term reliability.

Another standout feature is the modular design, allowing for easy upgrades and customization. Whether you need to integrate additional cooling systems or adapt to new material types, our machine offers flexibility that future-proofs your investment. We also prioritize safety with embedded emergency stops and overload protection, ensuring a secure working environment. By comparing side-by-side, users quickly notice the attention to detail—from the robust frame to the silent operation—that sets our extruder apart as a premium choice.

What is the typical lead time for delivery and installation?

Delivery usually takes 4-6 weeks after order confirmation, depending on your location. Installation can be scheduled within a week of arrival, and we provide on-site support to ensure a smooth setup process.

How does the machine handle different grades of POM material?

The extruder is designed with adjustable parameters for screw speed, temperature zones, and pressure settings, allowing it to accommodate various POM grades seamlessly. Our technical team can guide you on optimal configurations for your specific material type.

Is training provided for new operators?

Yes, we offer comprehensive training sessions covering operation, maintenance, and troubleshooting. These can be conducted on-site or via virtual platforms, tailored to your team's experience level.

What kind of maintenance is required, and how often?

Routine maintenance includes cleaning the screw and barrel every 500 operating hours, lubricating moving parts monthly, and inspecting electrical components quarterly. Detailed checklists are provided in the user manual.

Can the machine be customized for specific sheet dimensions or outputs?

Absolutely. We offer customization options for sheet width, thickness, and production speed. Discuss your requirements with our engineers during the quoting process to tailor the machine to your needs.

What warranties and support services are included?

The machine comes with a standard 2-year warranty on major components. We also provide 24/7 technical support and access to spare parts to minimize any potential downtime.

Embracing this technology means stepping into a world where efficiency and quality coexist. At Qingdao Eaststar Plastic Machinery Co., Ltd., we’ve poured decades of expertise into every aspect of the POM Sheet Extruder Machine, ensuring it meets the dynamic needs of modern industries. From its resilient build to its user-centric features, it’s engineered to deliver not just products, but possibilities. Explore how this machine can transform your production landscape and drive your business toward unprecedented success.