PE PP Sheet Extruder Machine,PA POM Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

Welcome to the forefront of modern manufacturing innovation with the HDPE Drainage Board Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This cutting-edge equipment is engineered to produce high-density polyethylene (HDPE) drainage boards, which play a critical role in various construction and environmental projects. From foundation drainage to landscaping and civil engineering, these boards ensure efficient water management, preventing waterlogging and extending the lifespan of structures. Imagine a world where every building foundation is safeguarded against moisture damage—this machine makes it possible by delivering consistent, high-quality drainage solutions that meet global standards.

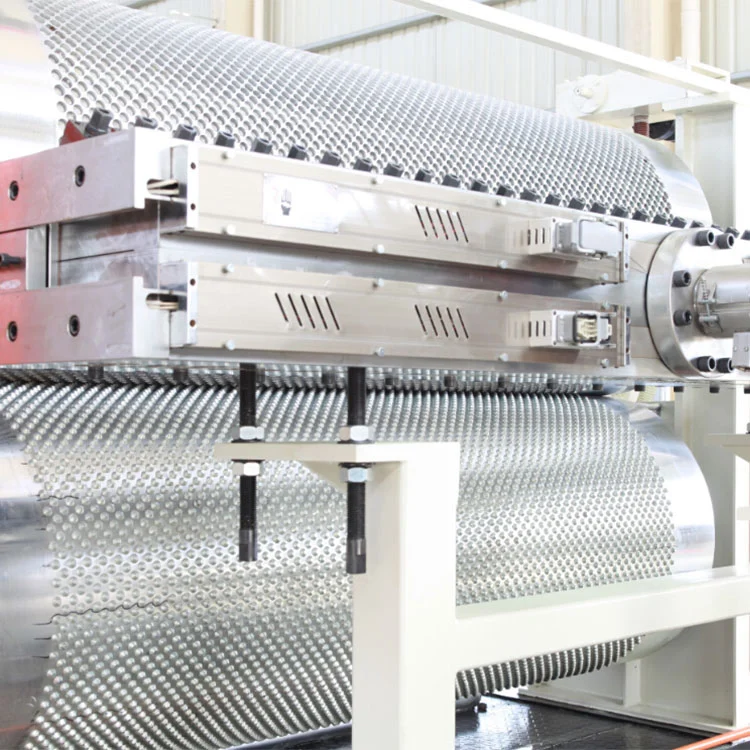

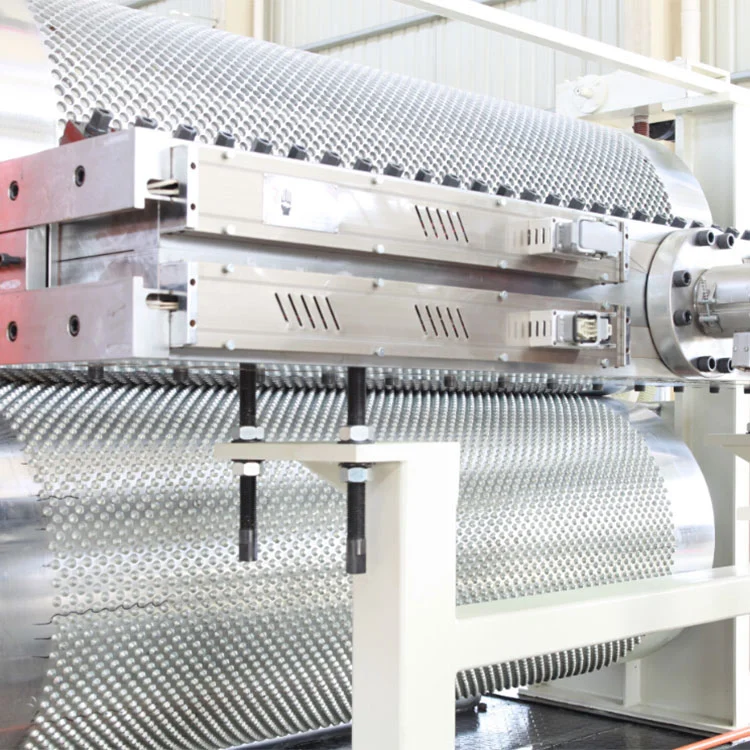

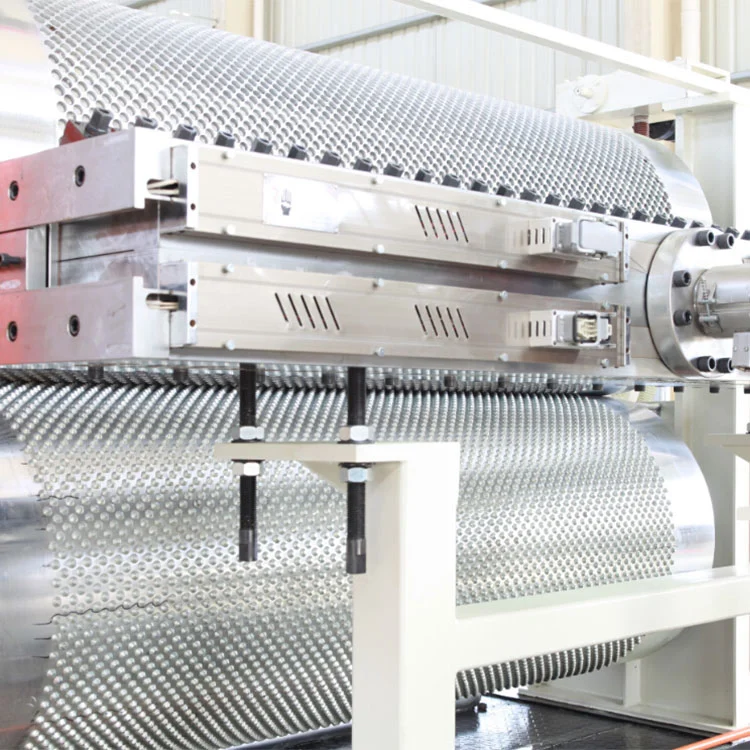

At its core, the HDPE Drainage Board Extruder Machine excels through superior design and advanced technology. Crafted from durable materials, it features a robust extrusion system that minimizes energy consumption while maximizing output. The machine's precision control system allows for seamless adjustment of board thickness and pattern, ensuring each product meets exact specifications. But what truly sets it apart is its reliability—backed by Qingdao Eaststar's decades of expertise, this extruder operates smoothly under demanding conditions, reducing downtime and maintenance costs. With a focus on user-friendly interfaces, operators can easily monitor production parameters, making it ideal for both seasoned professionals and newcomers to the industry.

Let's dive into real-world scenarios where this machine shines. Picture a construction site plagued by poor drainage, leading to delays and increased costs. Traditional methods often fall short, but the HDPE Drainage Board Extruder Machine offers a game-changing solution. By producing lightweight yet sturdy boards with excellent water permeability, it addresses common pain points like soil erosion and structural instability. For instance, in highway construction, these boards facilitate subsurface drainage, preventing road damage. In agricultural settings, they enhance irrigation efficiency. The machine's versatility is unmatched, adapting to various materials and custom requirements.

To illustrate its capabilities, consider the following table summarizing key parameters that highlight its performance. This data reflects typical operational metrics, helping you visualize how it tackles specific challenges:

| Parameter | Specification | Benefit |

|---|---|---|

| Output Capacity | Up to 500 kg/h | High efficiency for large-scale projects |

| Power Consumption | Optimized at 100-150 kW | Reduced operational costs and environmental impact |

| Board Thickness Range | 10-50 mm | Versatility for different applications |

| Material Compatibility | HDPE and recycled plastics | Eco-friendly and cost-effective production |

Who benefits most from this innovation? The HDPE Drainage Board Extruder Machine is a must-have for construction companies, civil engineers, landscape architects, and environmental consultants. Whether you're working on residential complexes, industrial parks, or public infrastructure, this machine streamlines production and ensures reliable drainage solutions. Imagine the satisfaction of completing a project on time, without weather-related setbacks. Users often report feeling more confident in their work, knowing that the boards produced are durable, resistant to chemicals, and designed for long-term performance. It's not just about meeting deadlines—it's about building a legacy of quality and sustainability.

What makes this extruder stand out in a crowded market? Unlike conventional machines, Qingdao Eaststar's HDPE Drainage Board Extruder Machine integrates smart automation features, such as real-time monitoring and automated calibration. This reduces human error and enhances consistency. Additionally, its modular design allows for easy upgrades and maintenance, future-proofing your investment. Competitors may offer similar outputs, but few can match the combination of energy efficiency, customization options, and after-sales support provided by Qingdao Eaststar Plastic Machinery Co., Ltd. It's a tool that grows with your business, adapting to evolving industry demands.

Now, let's address some common questions to help you make an informed decision:

What is the typical lifespan of the HDPE drainage boards produced by this machine?

The boards can last over 50 years under normal conditions, thanks to HDPE's resistance to UV rays, chemicals, and physical stress. This durability ensures long-term cost savings and environmental benefits.

How easy is it to operate the extruder for someone new to this technology?

Very straightforward. The machine comes with an intuitive interface and comprehensive training support from Qingdao Eaststar. Most operators become proficient within a few days, minimizing the learning curve.

Can the machine handle recycled materials without compromising quality?

Absolutely. It's designed to process both virgin and recycled HDPE, promoting sustainability while maintaining high output standards. This flexibility helps reduce material costs and supports green initiatives.

What kind of maintenance is required, and how often?

Routine checks every 500 operating hours are recommended, focusing on the extrusion screw and heating elements. With proper care, the machine requires minimal downtime, ensuring continuous production.

Is customization available for specific project needs?

Yes, Qingdao Eaststar offers tailored solutions, including adjustments to board dimensions, patterns, and production speed. This ensures the machine aligns perfectly with your unique requirements.

Embracing the HDPE Drainage Board Extruder Machine means investing in efficiency, reliability, and innovation. From its advanced engineering to its positive environmental impact, this equipment empowers businesses to tackle drainage challenges head-on. Whether you're expanding your production capabilities or entering new markets, Qingdao Eaststar Plastic Machinery Co., Ltd. stands by your side with proven expertise and unwavering support. Explore the possibilities today and transform your projects with confidence.