PE PP Sheet Extruder Machine,PA POM Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

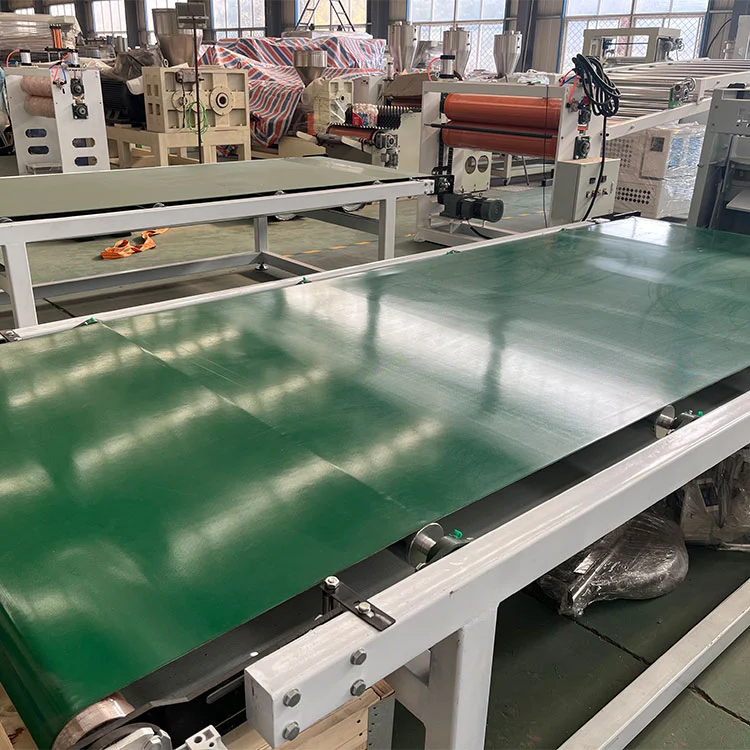

Welcome to the future of plastic board manufacturing with the ABS Double-layer Co-extrusion Board Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. This advanced machinery is designed to produce high-quality, durable ABS boards with a double-layer structure, offering superior performance for various industrial applications. Whether you're in the automotive, construction, or packaging industry, this machine ensures precise extrusion, consistent output, and enhanced material properties. By integrating cutting-edge co-extrusion technology, it allows for the creation of boards with distinct layers, each tailored for specific functionalities like impact resistance, UV protection, or aesthetic appeal. Say goodbye to single-layer limitations and embrace a versatile solution that elevates your production line to new heights.

At the heart of this machine lies its innovative co-extrusion capability, which enables the simultaneous extrusion of two different ABS layers. This results in boards that combine the best of both worlds: a tough outer layer for durability and a flexible inner layer for impact absorption. The machine boasts a robust construction with high-grade components, ensuring long-term reliability and minimal downtime. With features like automated temperature control, precision die design, and energy-efficient motors, it reduces operational costs while maximizing productivity. Users benefit from consistent board thickness, smooth surface finish, and excellent dimensional stability, making it ideal for applications where quality cannot be compromised. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs this with a comprehensive warranty and dedicated technical support, giving you peace of mind in your investment.

Many manufacturers face issues like inconsistent board quality, high material waste, and frequent machine breakdowns. The ABS Double-layer Co-extrusion Board Machine tackles these head-on by delivering uniform extrusion, reduced scrap rates, and enhanced durability. For instance, its advanced screw design ensures optimal material mixing, while the dual-layer setup allows for customized properties like flame retardancy or color consistency. Below is a table highlighting key parameters that demonstrate its efficiency:

| Parameter | Specification |

|---|---|

| Extrusion Width Range | 600-2000 mm |

| Production Speed | Up to 8 meters per minute |

| Layer Thickness Control | Precision within ±0.1 mm |

| Power Consumption | Optimized for energy savings, approx. 45 kW |

| Material Compatibility | ABS, with options for other polymers |

This machine is a game-changer for businesses involved in producing items like automotive interiors, building panels, protective casings, and consumer goods. Its versatility makes it suitable for small to medium-sized enterprises looking to scale up, as well as large corporations aiming for precision and efficiency. Common usage scenarios include manufacturing lightweight yet sturdy partitions, decorative boards with vibrant colors, or components requiring high impact resistance. By investing in this equipment, companies can streamline their operations, meet stringent industry standards, and cater to evolving market demands with ease.

Imagine the satisfaction of delivering flawless products every time, with boards that withstand harsh environments and maintain their integrity over years. Users of the ABS Double-layer Co-extrusion Board Machine often report a significant reduction in rework and customer complaints, leading to higher profitability and brand reputation. It solves common pain points such as delamination, color fading, and structural weaknesses, empowering businesses to focus on innovation rather than troubleshooting. The emotional payoff is immense—confidence in your output, pride in your craftsmanship, and the ability to take on more complex projects without hesitation.

Compared to standard extrusion machines, this model from Qingdao Eaststar Plastic Machinery Co., Ltd. excels with its modular design, allowing for easy customization and upgrades. The dual-layer technology not only improves product performance but also opens doors to innovative applications, such as boards with integrated insulation or antimicrobial properties. Additionally, its user-friendly interface and remote monitoring capabilities reduce the learning curve for operators, while the eco-friendly operation aligns with sustainable manufacturing trends. These unique aspects make it a preferred choice for forward-thinking companies.

What is the maximum board width this machine can produce?

The ABS Double-layer Co-extrusion Board Machine supports widths from 600 mm to 2000 mm, with customizable options based on your specific requirements. This flexibility ensures it can handle a wide range of project sizes without compromising on quality.

How does the co-extrusion process enhance board properties?

Co-extrusion allows for the combination of different ABS materials in distinct layers. For example, one layer can provide UV resistance, while the other offers impact strength. This results in a multifunctional board that outperforms single-layer alternatives in durability and application scope.

Is the machine easy to maintain?

Yes, it features a modular design with accessible components, making routine maintenance straightforward. Qingdao Eaststar Plastic Machinery Co., Ltd. provides detailed manuals and online support to guide users through cleaning, part replacements, and troubleshooting, minimizing downtime.

Can it handle materials other than ABS?

While optimized for ABS, the machine can be configured for other thermoplastics like PP or PS with minor adjustments. Consult with our technical team to explore compatibility and achieve the best results for your material choices.

What kind of technical support is available after purchase?

We offer comprehensive support, including installation guidance, operator training, and 24/7 remote assistance. Our global service network ensures prompt responses to any issues, helping you maintain peak performance throughout the machine's lifecycle.